Clarification: When I write “work a job fair”, I mean how to get the most out of it as a student or job seeker. This could be confused with the fact that I sometimes recruit at job fairs, but I thought this should be brought up at the beginning after I re-read the article.

In talking to a fellow engineer about to attend a career fair, I realized I had some advice for him, having gone so many times in the past. I’ve even been back a few times to recruit for my current company and being on the other side of the handshake is an interesting insight into the do’s and don’ts.

- As soon as you realize they want you to apply online, ditch.

- First off, this was a pet peeve of mine as an attendee and is to this day. As soon as HR departments at large companies realized they could just use computers to filter the resumes of prospective employees instead of reading them (yeah, I’m looking at you Big Blue), they did it as fast as they could. The result was that you now walk around job fairs talking to people and handing out resumes, only to assume those people will be throwing it away ten minutes later (“Why did I print that on paper that costs 50 cents a sheet?!?”). In the event you’re talking to someone from a company and you even overhear a different recruiter asking someone to apply online (assuming you hear it before you’re told directly to do so), kindly end the conversation with the person you’re talking to and write in your notes to apply later. Job fairs are to make first impressions; if the employers’ representatives are not taking notes on the people they are talking to, they really are only wasting your time.

- Be excited

- Enthusiasm is contagious. It can make any conversation more exciting and in the case of the recruiters, less routine. They have many of the same conversations over and over throughout the day, often with people that don’t show particular enthusiasm for what they are talking about. More importantly, enthusiasm about your chosen field is a precursor to another trait that I feel is particularly important in any field: passion. Without it, you probably won’t be able to hold your interest long enough to become an expert in your field. And I mean a real expert, not like those silly people online that start blogs and call themselves experts. Haha.

- Be excited, but show a little modesty

- Before you go off the rails and start spouting all of your best characteristics to a potential employer, remember a few things:

- Designing something in school is much different than designing something in the real world.

- No one wants to hear every single detail of your design project upon first meeting you.

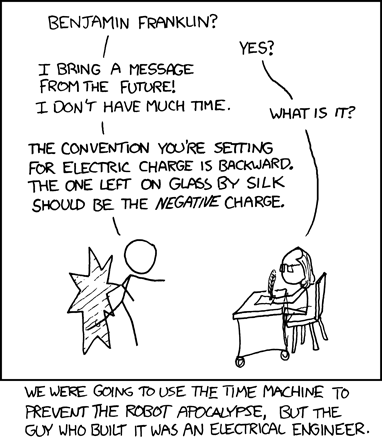

- As an engineer, getting a design job just out of school is difficult and unlikely. The majority of engineers use their degree to launch into other types of jobs. I’m not saying you shouldn’t shoot for a design job if you want one, I’m just saying the expectation shouldn’t be that you will be handed one (and you should keep your mind open to all opportunities).

- If you present your past work correctly, the work will speak for itself. In fact, succinctly describing your achievements in an understandable way will help to show your enthusiasm much better than you trying to squeeze 500 words into a 1 minute time period. Show them that you are really proficient in the area you’re targeting and you’ll get recruiters clamoring to know how much you really know (and eventually what it’ll take to get you on their team).

- Before you go off the rails and start spouting all of your best characteristics to a potential employer, remember a few things:

- Forget the give-aways

- The pens and t-shirts and yo-yo’s and other stuff they give away at these events are fun to get and sometimes quirky, but essentially worthless. If you want to get free stuff with a logo on it, go get the job from the company and worry about the branded crap later. Focus your time and resources on meeting people, not collecting widgets.

- Figure out what skills they’re looking for

- No amount of preparatory work researching the companies you’re targeting will let you know what skills a company is looking for. Hell, it’s in the company’s interest to be vague when they list what kind of employee they’re looking for so the maximum number of people will stop by their booth. This is one of your most important tasks at career fairs; in fact, it’s one of the few reasons to stick around and continue talking to a representative from a company once you have found out they only accept applications online. Talk to the engineers that work in groups you would want to work in (wait to talk to them if there is a line) and find out what they look for in potential candidates. In fact, ask them that, “What do you look for in potential candidates who would be hired for YOUR position?”. It might sound a little weird, like you want to replace them with yourself, but it’s the most direct way to know what skills and techniques you need to have to work there. If you have those skills, awesome. If you don’t, work on getting those skills, however you can.

- Know what you like and don’t like and tell them about it

- This hearkens back to being enthused about the field you’re studying. In the event you’re not very capable in transmitting your enthusiasm to the person you’re talking to, stating what you do and don’t like can help to showcase what you’re really trying to do with your career. But it’s also important because you can narrow down the companies that can actually offer you a job. If you’re really interested in embedded systems but you’re talking to a company that only works on designing silicon, stating what you’re interested in can be a real time saver. If you’re not particularly fond of working on spreadsheets or databases and you say so, you can quickly be informed by the company you’re talking to that those things would be the main job function of any potential employees. In stating what you really like and dislike, you basically turn a career fair into a speed-dating service, quickly going through all of the options at a particular event and honing in on those that have real potential.

- Brush your teeth. Wear a clean shirt. Don’t be a robot.

- I only wish this was more obvious to people than it is. I’ve already been pointing out that career fairs are only as useful as the impressions you make on potential employers; sometimes it’s also about the resume you hand them. But if the whole ordeal is about impressions, some people don’t get it. Look decent, smell decent, smile decent. These are all things that are easy but immediately put you out of the running if you get them wrong. Remember the lollipop first question for $100 on “Who Wants to be a Millionaire”? Remember some of the dodos who got it wrong and had to immediately leave the stage? Don’t be one of them.

Do I know everything about job fairs? No, I know very little. I personally never really liked them as a potential employee. I’d rather stand out to an employer by connecting on a personal level with a recruiter and then showcasing what I know. There just isn’t time for that at career fairs. But if you or the employers you’re interested in working for consider career fairs a necessary evil, I think the tips listed above can have a positive effect on some of your interactions.

What kinds of things do you try to do at job/career fairs? Can those things be done by engineers at career fairs or are they specific to another profession? Please let us know in the comments.