Boy is it hot in here or is it just me? Why’s that gizmo over there giving off so much heat?

Power budgets are a necessity these days. Due to increasing regulation, we’re seeing devices that must comply with efficiency limits in their power conversion (using a switching power supply or otherwise).

So what is a power budget? Much like a budget you might have for your personal finances, a power budget shows where all the possible power will be used by a device to by breaking it down into components and categories. In some situations, you might be told up front that you will have 3W available to run your design. However, sometimes as designers we start by calculating the total power a system needs and then taking actions such as replacing parts or redesigning circuits to cut back power to an acceptable level. So why might someone want to do a power budget from day one?

- Power availability — While you might have more power today, it doesn’t mean you’ll have it tomorrow. Designing a system for 3 W power consumption may be acceptable now, but designing a lower power system may meet future regulations. And the trends in the industry point in that direction.

- Battery Life — If your device is running off a battery, you likely do not have a choice whether you are doing a power budget. You want to maximize the life of your device on a single charge (assuming it is using rechargeable batteries) and your customers want the same. Just a few weeks ago I was complaining publicly on The Amp Hour about my new device with poor battery performance. Doing a power budget will point to the components consuming the most power so you can later optimize for longer battery life (hopefully this was a design constraint from the beginning).

- Heat generation — Heat is an unfortunate side effect of working with electronics. However, it also has a 3 direct effects on your product and how it is used.

- User discomfort — No one likes having a hot laptop sitting in their lap. Nor a cell phone that is uncomfortable to hold.

- Circuit robustness — An often quoted specification of an op amp is the voltage offset drift. This sensitivity to temperature can have dire effects in systems that rely on analog accuracy. However temperature changes can create conditions that are unfavorable and could even cause device failure (such as thermal runaway). The heat of the whole system can end up affecting individual components as the nominal temperature inside your device rises.

- Product lifetime — The lifetime of a product can be drastically reduced by higher than normal temperatures inside the device. Extreme temperatures can begin to dry out capacitors and cause others to fail catastrophically. While it is possible for systems to fail in a drastic manner, the more likely outcome is a product that does not last for its specified lifetime. An example might be a TV that has a less vibrant LCD after 5 years due to excessive heat and component drift and fatigue. If the product was designed to have lower heat, the product would have lasted longer. For more on how to design and prevent early failures, check out Dave’s video blog about heatsink design.

- Cost (sizing) — More power means you need larger components. Other than the obvious requirement of needing more space (duh), it often correlates to higher cost components. Not only will you need larger packages for your components such as op amps and comparators in order to better dissipate heat. You’ll also need a larger power supply with more reliability. If a 5W and 20W power supply with 12V output are compared, the 5W supply has smaller magnetics and less wiring because there is less total current that needs to pass through.

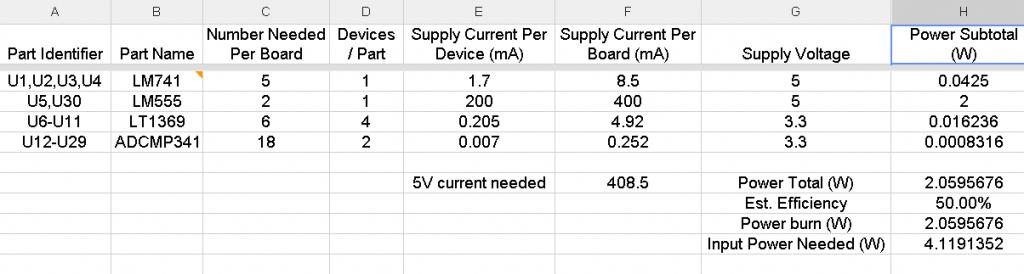

So let’s look at an example power budget (click for a larger version):

As you can see, not much more is required than your datasheets and a spreadsheet type program. Even simpler is a piece of paper but I prefer the built in math functions of the spreadsheet program. The first two columns (A&B) are simply identifiers to allow you to recognize which components correspond to which set of data. The next two columns (C&D) determine the multiplicative factor. If you have 5 components that contain 4 op amps per, then that will consume 20x the power of a device that has the same supply current needs but only one op amp per and there is only one on the board. The next two columns (E&F) show how much current each individual component contributes and then the sum of all the components of that type contribute. Note that this parameter on a data sheet would be listed as “supply current” or “active current”. The “quiescient” number is when the device is in a resting state and will likely be much less than the active number (and not relevant for this example). Finally, the supply voltage is listed (in column G) to calculate power (using the formula P=I*V) which is listed in column I per device. All of these contributors are summed, an efficiency is estimated (I assumed a poor efficiency linear type supply) and the total power required input to the device is given. Further calculations could result from much of this initial data.

I would be remiss without mentioning something about power budgets: you’re still going to guess about certain things. In fact it will be many different things. You might not have perfect data about your components. You might not completely trust the “typical spec” of one of your components. This is the point where you design in a margin of error. However, just like many other aspects of engineering, this is where tradeoffs come into play. You might want to design in 4 times more power capability than you calculate (to feel safe), but there are cost and spec requirements to consider. You will have to determine how confident you are in your design and how many resources you have available to your design. In the above example where the 5V parts require 408mA from the supply (~2W), I might over spec the part by designing in a part that is capable of supplying 600mA. The (50%) margin of error allows for future expansion (might need to solder in an extra part or two) and also gives a cushion if anything was miscalculated. In some situations this 50% might be too much (think a very low-cost, high volume design) or might be too little (think a military, high reliability design). It all depends on the situation and requirements.

Power budgets can be very powerful depending on the amount of time and effort you put into them. Otherwise they are educated guesses which may or may not be helpful to your project; how helpful they are might also depend on where you are in the design cycle. As stated before, these budgets are more and more of a necessity in a world more power conscious and with devices that continue to shrink. Your customers will expect longer battery life and your products to have yet more features. Teach yourself how to do power budgets now and it will pay dividends for you in the future.

[xyz_lbx_default_code]