A note about part reviews: I do not get paid to do reviews. I am either doing them out of the kindness of my heart, because they have some historical significance (as in the case of my review of the LM741) or most likely I think the technology is important and interesting. All opinions are my own and I would not suggest making any part choices based on the information in this article alone. Read some datasheets, they’re pretty informative.

No wire is perfect.

Basically, that’s the premise behind this chip, the LT4180. The real background is that when someone is providing power to a remote device they want the voltage to be accurate.

An example of this might be a USB supply to a device more than 20 feet away. The host (whatever is in charge of setting up communication and providing power, such as a computer) is supposed to supply 5V to the device (such as a printer or a mouse). In this case let’s assume that the device is very dependent on that voltage being correct, for one reason or another. The real problem is that the wire providing that power has some innate resistance to it. Even a resistance of 1 ohm at 500 mA (the max current of USB) can cause a drop of .5V. That’s 10% of the intended voltage!

So what are the traditional options? Well, the best one is to have a separate set of wires known as “sense” wires. They detect the voltage directly at the device without drawing much current (likely by utilizing high input impedance op amps). So the current that is powering the remote device will be sourced through one set of wires and the voltage at the device will be fed back to the whatever is supplying the voltage. In theory if the resistance of the wire changes (due to temperature, stress, etc), the controller will react and adjust the voltage up or down so the correct voltage is delivered to the device.

But what if you already ran your wires and you can’t run a second set to sense the remote voltage? You either design in a regulator on the device side (a good idea regardless) and source a higher voltage or you just design in devices that can handle a large swing of voltages. Neither is the best idea, though they are likely to be cheaper than using this part. At $3 minimum price you’re much more likely to find a cheapo linear regulator which you can put on the device end and then burn power there. You lose efficiency but gain a few points with the MBAs in your company.

Enter the LT4180. You can put this device in line with a voltage regulator, as shown on page 6 of this wonderful app note.

As a quick aside, you know LT cares about this product as Bob Dobkin, the co-founder and Chief Technology Officer at Linear, co-wrote the app note. Very cool, you don’t see high level execs getting their hands in on the action very often these days. I was impressed at least.

Back to the app note itself, you’ll see that there is a switching regulator or linear regulator that is providing the initial voltage. Then this device sits between the voltage regulator and the wires that lead out to the device. Notice also that there are only two wires, a source wire and a return wire.

Now for the magic. It has two key pieces, explained in better detail in the app note, but summarized here.

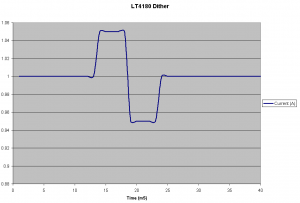

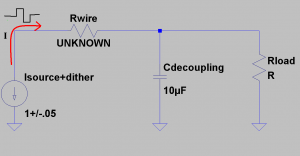

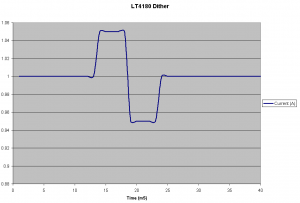

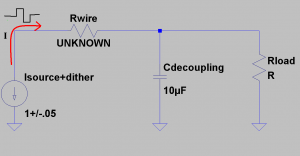

The Dither — LT calls it an algorithm, but in effect they are only stepping the supply current up and down by 5%. So if the initial regulated current is 1A, they step it up to 1.05 A and then down to .95 A (similar to what is shown below with a different timescale). Why? Because it’s effectively forcing an AC (varying waveform) through what was a DC (non-varying) channel.

Doing so allows you to gather the impedance of the channel without directly measuring the drop due to the resistance in the wires that are sourcing current. According to the app note:

Because C is sized to produce an “AC short” at the square wave frequency, the interrogating voltage square wave produced at the power supply is equal to VSUPPLY(AC) = 0.1 × IDC × R, measured in Vpp. The voltage square wave measured at the power supply has a peak-to-peak amplitude equal to one tenth the DC wiring drop. This is not an estimate—it is a direct measurement of the voltage drop across the wiring over all load currents.

As illustrated below, the AC square wave is now shunted to ground instead of going to the load. This is how you can be certain it’s the actual resistance of the channel and not the channel AND the load. How cool is that?

The Control — Wait a second, how do they do that when they are not a part of the switching regulator or linear regulator? Nor does the regulator have any control lines with SPI or I2C or similar? LT illustrates 2 ways, but the basic idea is the LT4180 feeds back an analog voltage to the controller. This can then be used in myriad ways. The most straightforward way is to feed this voltage back to an error amplifier on the regulator, if it has one. The error amp will interpret any incoming signal as an error and correct the output. By dithering this signal by a little in either direction, the output current from the regulator can be made to vary. Other methods shown include feeding the signal into the trim circuitry (that controls the precise voltage allowed by certain regulators) or even feeding it into a discrete MOSFET based current source. With the voltage feedback signal there are certainly a lot of creative ways to feed this information back to your regulator/switcher to achieve the desired dither.

All in all, I was impressed by this part. I haven’t had it on my bench yet to try it out, but the idea alone made it intriguing enough to write about. Power is a really big market and growing and Linear Tech makes no secret of the fact that they are targeting the more obscure but lucrative problems such as this one. I’d like to reiterate that the app note is fantastic for this part and the datasheet fills in technical details and specifications that aren’t in the app note. Hopefully I made what was already well written a little easier for others to comprehend on the first pass.

For people that have landed on this page from Google, I would prefer that you do not ask any design questions, I am not actively using this part and I’m sure there are many others out there that would serve you better. For everyone else, if you have any questions, please leave them in the comments. Thanks for reading!