If it hasn’t already been painfully obvious, I’m trying to learn mechanical stuff. Odd for a site that’s supposed to be about electronics, but I’ll get back to that on here eventually. Hopefully you’ll stick around until then. I’ve found that working with the mill has me looking at mechanical problems in a completely different light and has made me a better system designer overall.

As for these videos, I took the whole thing apart, mounted the base to my bench, put it back together, oiled it (not shown in video), leveled it and attached the stepper motors. I now have a functional machine!

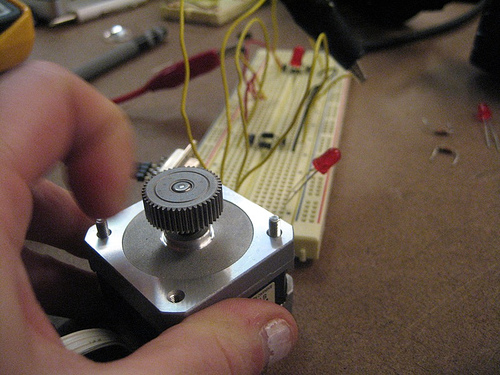

Thanks to megananne for the featured image photo

3 replies on “Disassembling and Reassembling a Mill”

Thanks for this video; My Dad has a machine shop and I know almost nothing about using his equipment in the shop. These videos are very informative, and I do admire your willingness to just jump in and starting learning Machine Shop 101 basics. Again, I admire your willingness to learn new things, and your videoing these steps, in order to help other newbies.

Thanks Again

James Lacy Kamuf

I think the quote you were looking for at the beginning was “Don’t turn it on, pull it apart”.

I’m sure I’ve heard it from Dave on the EEV blog.

“Odd for a site that’s supposed to be about electronics” – well, not for a site about *analog* electronics! There are quite a few parallels between mechanical engineering and analog electronics engineering. Oscillating springs, helical gears, pendulums, force dividing levers etc. – if you abstract it enough, you might as well be thinking about an analog electronics circuit. So, I think you’ll feel right at home in mech!