So I finally got my new end mills in the mail and got to the store to buy some 6061 aluminum (good prices on the clearance rack at The Metal Store!)

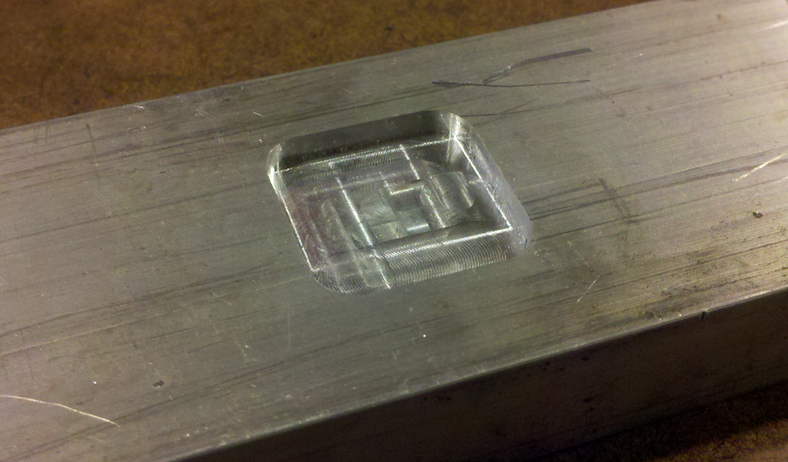

Anyway, here is my super simple first cut. As I said on Twitter, it feels much like the first time I made a PCB. Nothing even remotely special about this cut, just that I was the one to do it. Guess that’s the power of making.

7 replies on “So Metal…”

The “Gold” coating I suspect is Titanium Nitride. Looks like fun, took me back to my college CNC classes.

Have you considered opening a hackerspace in your basement?

Don’t think the wife would let that one fly. I have enough trouble managing myself, let alone having others down there!

What a cute little mill! It almost makes me feel that I can begin CNC on my budget. What an excellent share chris, keep up the good work!

Plunge cutting with a mill requires a two flute or a 4 flute designed to clear the metal under the mill bit or you get that aggravating squeaking noise as the cuttings build up under the milling bit. Cutting speed is based on cutter outside diameter and feed rate think of each rotation of the bit and how deep the cutting edges are in the metal a pretty good reference for aluminum is 6 thou per tooth steel is about 3.. In your video looks like about 1000 rpm 1 inch per sec and 4 flute with a 3/8 th cutter,,, 60 inch per minute feed rate / 1000 rpm / 4 flutes / 1.25 (circumference of the bit) =12 IPT (inch per tooth) cutting your feed rate in half would bring you down to about the right cutting rate of 6 here is a pretty good online calc

http://www.custompartnet.com/calculator/milling-speed-and-feed … take care happy milling !

Hey Chris, just wanted to say good luck with your machining adventures! I’m a machinist who’s learning some electronics, so I kind of know how you feel. The first time I got my arduino to blink some LED’s I felt like some kind of genius! We’ve all got to start somewhere, right?

[…] — Remember how I used to write about my new toy, my Taig mill? I started with it about a year ago and then decided I wanted to work on a part time gig that could […]