I used to read Popular Science religiously. Those great stories about the new technologies were so exciting, sometimes I had trouble sitting still. And the best part was turning to the back where you could buy some DIY kit! I remember there were “lightsabers” and “hovercrafts” and flying vehicles, all available in kit form. I have since stopped reading Popular Science, but I could very easily imagine some of those ads on the back. One might just happen to read “Batteries no longer necessary. Ultra-capacitor is the wave of the future! Cheap energy for all!”. Of course, these are in fact the headlines for an Austin based company EEStor.

So I’m going to say it. I don’t think EEStor will deliver on the hype surrounding them. Even the more recent endorsements from third party auditors, a deal with Lockheed Martin and their ongoing partnership with ZENN motors does not make me think they can produce an award winning product any more than other companies out there could. Part of me thinks there are signs that prove this (explained below) but the other part of me is secretly hoping this is one of those situations where I say something will never happen and then it immediately does. This could be called “self-reverse-psychology” or “deluding myself” or even just “being wrong”, but who cares? I just don’t see it in the cards for EEStor and I’m not the only one.

Oh sorry. I forget sometimes that the only people who fall into reading my blog are my lovely friends and hopefully a few casual browsers. EEStor is a company that claims they have and are continuing to develop an “ultra-capacitor” capable of producing capacitors with extremely high capacitance, thanks to a new dielectric material, barium titanate. But real quick, let’s look at capacitors in general for anyone who might not have the whole picture. (Maybe skip down the page if you know how capacitors work).

The simplest capacitor possible is two flat plates of metal, connected to a DC electricity source:

When you turn on the source, charge flows to either side of the plate, but cannot pass through. In this case it cannot pass through because of the air in between the plates; here, the air is the dielectric.

Ok, so now there is charge stored on either side of the plates…but what good does that do? Well, there are myriad uses for the capacitor in the world of science and otherwise; but in the most basic definition, a capacitor exists to store energy. Furthermore, the higher the capacitance of a capacitor, the more energy it can store. So how do we get that capacitance to be higher? Let’s look at the equation (real quick, I promise and then no more equations).

Here C is capacitance, A is the area of the plates, d is the distance between the plates, and ε is something called the permittivity of the dielectric. So to make C bigger, we either need to make A or ε much bigger or d much smaller. At first I thought EEStor was trying to only find a better dielectric (with a higher value for “ε”), which would look like this:

This shows that the charges being closer together, but in reality, it’s that the material between the plates allows the electric field to permeate through to the other side better than air. This approach of having a better dielectric is actually closer to an electrolytic type capacitor.

However, EEStor is trying to make a better ultra-capacitor. So back to the formula (last time). Ultra-capacitors try to change everything in the formula. To maintain overall size of capacitors, the area of the plates (“A”) is changed by adding material with higher surface area (Wikipedia lists a possible material as activated charcoal). This gives the charges on each plate more places to rest. Next, the distance between the plates (“d”) is reduced to be as small as possible, down to the nanometer range. This is where most ultra-capacitor manufacturers stop. They use an ultra-thin dielectric layer with a standard permittivity (“ε”) and then surround the capacitor in electrolytic fluid. This limits the overall capacitance and the material properties of the current dielectric also limits the amount of voltage (potential energy), usually to around 3V (rather there is a trade off between voltage rating and capacitance).

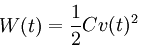

EEStor is trying to change all of this by using a dielectric with a much higher value. They use barium titanate, which in a powder form has a very high dielectric constant and very high tolerance to voltage. They claim to compress the material to a pure form in a very thin layer (up to 99.9994% purity, they claim), which should maintain that high dielectric constant; however, this is up for contention. If they do manage to purify the material, they will be able to put a much higher voltage across the dielectric without fear of material breakdown, which they claim is main benefit of using barium titanate. Additionally, they use many different layers of the dielectric and other plates in order to create a higher capacitance. Why, you ask? Because the work (Energy * charge) a capacitor is capable of producing is equal to

That means if you are capable of increasing the voltage rating of a capacitor (how much it can handle before the dielectric breaks down or blows up), the work goes up in a square relation to that higher voltage (doubling the voltage yields 4 times the work). You can have a much higher energy density in the device, making the operation appear to be closer to that of a battery.

Alright, so we’re finally at the point where I explain why I think that EEStor won’t deliver on their promises. First, let’s look at what they have promised:

- A working prototype by the end of 2008. A fully implemented device in a ZENN vehicle by the end of 2009.

- A Capacibattery at half the cost per kilowatt-hour and one-tenth the weight of lead-acid batteries.

- A selling price to start at $3,200 and fall to $2,100 in high-volume production.

- Weighs 400 pounds and delivers 52 kilowatt-hours.

- The batteries fully charge in minutes as opposed to hours.

Yikes. Those are some pretty lofty goals. I’d say the most unbelievable of these is the first one (followed closely by the third). Since they haven’t shown the slightest sign of publicity, there really is not much to go off of. In fact, as a business model, EEStor has mystique as it’s main asset. They could go public with no product and have people bid up the stock price towards the sky with absolutely no product behind the curtain. In fact, the only people who have really stuck their head out to talk about this product is the CEO of ZENN motors, Ian Clifford. And why not? Even if the EEStor product (called the EESU) is a flop, ZENN motors can play the martyr and get the free publicity. But that’s all business. What about the technical stuff? Let’s look at some safety/efficiency/production concerns that could prevent them from making a product that can be mass produced at (relatively) low prices:

- ESR

- ESR stands for “Equivalent Series Resistance”. It is caused by imperfections in both the dielectric and the material that connects the capacitor to the rest of the world. The ESR is how much the imperfections impede the current flow, as the current works to align internal bonds (in both the capacitor and the connecting material). Normally, ESR will not have any effect at DC because it is assumed that there is no charging time. However, charging a battery or capacitor is more like an AC signal (albeit only half of a cycle), and the faster someone tries to charge it (in EEStor’s case, quite fast) the higher resistance will be. This will translate to heat in the capacitor and wasted energy. With the high currents being pushed through the capacitor at high rates, this becomes a safety concern first and an efficiency concern second.

- High Voltage

- This is really the key to the EEStor device. If they are ever planning to have a super fast charge, it will require higher voltages, likely on the order of kV. However, the high voltages have the obvious safety concerns (ZAP!) and the not-so-obvious concerns such as skin effects. Manufacturing a safe product that will pass automotive standards will be a difficult test. Consistently turning out a reasonably priced product that will safely deliver those same voltages will be even more difficult.

- Piezoelectric Effect

- Piezoelectric effect occurs when the crystal structure of a substance is stressed and then releases charge. The best piezos release charge all in the same direction based on their crystal structure. What happens when this box gets compressed, via a car crash? Will all of the charge be released at once? Will a fender bender turn into a ZENN car sponsored fricassee? (on a related, but unimportant note: If we go to all electric cars, what will happen in car chases in the future and they want to blow up the other car? Even though it doesn’t actually work, what will they shoot if there’s no gas tank? 🙂 )

- Material/Production Costs

- The product we have heard about so far, with extreme purity, will require a cleanroom-like setting, a foundry-like setting, or both (comparing it to what I know about fabs). In any of these scenarios, the cost of operation far exceeds what most venture capital firms are willing and capable of supplying in terms of cash. Unless they are quickly bought by a large scale producer of batteries or similar technologies, they would not have the working capital necessary to bring their production facility to a point where they are making enough units to create economies of scale (lowering the overall cost by averaging large fixed cost over all products produced).

- Manufacturing issues/Large scale manufacturing

- Aside from the material cost and the operations cost, let’s look at the obvious: making one of these units seems to be hard. I understand that they are developing processes to create these products, but the precision required for a consistent quality product could be so cost sensitive that they will drive the final part cost way past the projected $3200 price tag.

- Leakage

- Leakage would likely not be a barrier to production, but it would probably hurt them in their ability to deliver a product with the longevity needed to power cars. If the voltage across a capacibattery is supposed to be 1kV or higher, even with the best available insulators, there will be some amount of leakage (everything allows it). If the car was required to be plugged in while in a parking lot it would not be as big of an issue, but I don’t believe this is the model they are going for; they seem to want to deliver a standalone piece of equipment.

- Another way “leakage” can happen is across the dielectric. As capacitors age, the stress on the dielectric barrier eventually starts to break down and let electrons through. If EEstor does not properly monitor for DC leakage, there could eventually be catastrophic failure of the capacitor, as more and more current moves through the dielectric; this would heat up the device to unsafe temperatures and eventually cause a meltdown or explosion (exciting, but unsafe).

- Efficiencies

- Let’s say you have a “fueling station” that is actually capable of charging a ZENN car in minutes (as opposed to hours); it would likely require voltages on the order of kV as opposed to 10s or 100s of volts and currents that are on the order of amps. Let’s say for our example that we are trying to transfer 10 kW (10A * 1000V) . Even at 95% efficiency of power transfer (a very optimistic estimation), that means we would be wasting at least 500W everytime that we go to charge our capacicars.

- Infrastructure

- While my friend Nate would love to point out that the energy density of these devices still won’t approach that of gasoline or ethanol, they are proposing a product that comes closer than any others have yet. However, to achieve their miraculously fast charge times and high capacity capacitors, the product will require a charging station as mentioned above that is capable of deliving a high voltage payload to the battery (hopefully at a high efficiency). This means we’ll either need to convert gas stations into power stations or create huge step up transformers for the home. Remember, US line voltages coming into a house are 120V out of your wall socket. That will take some expensive equipment to safely regulate those voltages and convert to DC (another potential efficiency problem). The costs associated with implementing such a system (either commercially or in the home) could seriously hinder any chance of public acceptance.

So for the final piece of this ultra-capacitor manifesto, let’s look at the possible scenarios we might eventually encounter with EEStor. Aside from the skeptics, there are a good deal of people who are hopeful this company will succeed and fully expect it to; this outcome is possible, but the extent to which EEStor delivers will be up for anyone’s guess. As such, I’ve included a complementary predicition of the chance each will happen (in percentage):

- They deliver a “product” but it is only a fraction of the promised delivery-Perhaps they have an overzealous marketing person.

- Chance of happening: 40%

- They deliver a product but price it so high, there is no way to employ it in any commercial application for the next 5 years-Lockheed still might buy it. Lockheed’s interest is what got everyone so excited again back in May…but it doesn’t mean this product will be delivered or that it’s even possible.

- Chance of happening: 55%

- They deliver on all of their specifications and price targets

- Chance of happening: 5%

So go ahead EEStor, prove me wrong. I don’t want to seem like those people that said man would never fly or that there would be no need for more than 5 computers, I just wanted to write an article pointing out the difficulties that EEStor is likely to encounter and hopefully have already overcome. So EEstor, if you’re sending out samples and need a tester, I would be happy to play with one of your toys. And if you (the reader) think I missed any crucial points about ultra-capacitors or EEstor, please let me know in the comments.