Things get old. Things eventually do not work anymore. Even the best engineers cannot design a system for part failures (unless they have triple redundant systems, like NASA). It is for this reason, I have decided to document on my blog the tune up of my Wurlitzer 200A electric piano (seen below) as opposed to the usual analog issues in the workplace today.

I mentioned this piano in my post about keeping it simple, namely not replacing EVERY component, only the ones that require an upgrade/replacement. It is a famous piano that can be heard in many types of music, spanning rock, soul, jazz and more. Similar to the Fender Rhodes, the Wurly can be characterized by a darker, more over-driven sound and a built in vibrato (constructed from a simple oscillating circuit).

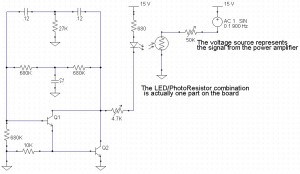

There are two components on these boards that need to be replaced the most often. The first is transistors, due to thermal stresses when they are over worked. In the case of my Wurly, the power transistors (seen below bolted to the large metal heat sink on the left) have started corroding, but have also had reduced output due to thermal stresses over the years. The board has upwards of 250 V and these transistors are ready to be replaced.

The other element that commonly needs to be replaced are the capacitors (the purple barrels seen above), specifically the electrolytic capacitors. An electrolytic capacitor is constructed by soaking paper in an electrolyte and sandwiching it between two aluminum plates (then attached to the leads of the capacitor). After about 10 years or so, the electrolyte begins to dry out and the capacitor degrades. Sometimes this can lead to a catastrophic breakdown (think “POP” or “BOOM”) or it can just mean that no signals will get through. Whereas I think of capacitors being frequency-dependent resistors (where the lower the frequency, the higher the resistance), these capacitors instead have resistance at ALL frequencies, due to the fact that the dielectric constant has gone from that of electrolyte to that of air. The final effect of all of this is a poorer sound, especially at the higher frequencies that are supposed to “pass through” a capacitor.

I am also hoping this will take care of some of the “hum” sound (most likely from 60 Hz); I’m hoping this will be resolved once the power filtering capacitors are replaced. I think that the ripple current may be higher since the capacitors have slowly degraded. This will impose the 60 Hz from the wall power onto the signal coming from the vibrating reeds (through the capacitive pickup). I also am wondering if the transformer (below) requires replacement, but I think I will replace the capacitors and transistors first.

That’s all for now, I will update more as I actually replace these capacitors. For now, enjoy the pictures and the sound samples (above links to Last.fm).