“Wha?”

That’s what you said when you read the title, isn’t it? That’s probably what I would have said. You said that for one of two reasons:

- You’ve never watched Firefly.

- You’ve watched Firefly and you just don’t get it yet.

The second is more excusable than the first. If you’ve never watched Firefly, I highly suggest going to do that right now. It’s 14 episodes (one season) and a feature length film. It’s a great show that was unfortunately cancelled after one season.

“So what the hell Chris? You’re sounding like a lame fan boy.”

Yes, yes I am. And I loved the show but I love the analogy much more. So let me explain the background on Malcolm Reynolds a bit before I dive into the relevancy to this site and electrical engineering.

Malcolm Reynolds, played by Nathan Fillion

Mal was the captain and owner of the Firefly (a spaceship). Prior to that, he participated in a war between the Alliance and the Browncoats, on the losing side. After the war (and where the show picks up), he is working with a small crew, floating through space and picking up jobs wherever they can. They aren’t always glamorous jobs but they often require ingenuity. Often times, they are avoiding the Alliance, which is a federation of the populated planets. They control just about everything in the galaxy and have very advanced technology. They seek to bring everything under their control.

Starting to see my point? I believe that engineers of the future (and already starting today), have only a couple options:

- Be part of the ever growing “Alliance” — In this case, the corporations (companies >200 people) that have an increasing share of the technological population.

- Be part of a smaller company (20-200 people). However, I believe that over time these smaller companies will continue to disappear (in the electronics world) because of the difficulty of competing on cost. They will either go out of business, see costs increase to the point of employees leaving (healthcare premiums, anyone?) or will get swallowed up by bigger companies.

- Work alone or in very small teams. Work on jobs for smaller companies in a contract situation. This would be where the future engineer is very similar to Malcolm Reynolds.

The corporations mentioned in the first point are large for many reasons, not all bad. One of the most striking is economies of scale; places like a semiconductor fabrication facility simply cannot operate with small budgets. They need capital equipment which is produced at great cost and the company is necessarily big in order to recoup the initial costs. Another is working with very advanced technologies. If you happen to be an engineer that is working with circuits that operate at 10’s to 100’s of GHz, you likely require very advanced equipment in order to monitor and modify your circuits. Only the largest companies will be able to afford the bleeding edge technology required to develop future technologies (i.e. If you’re working on 20 GHz signals, you need a scope that can detect 40 GHz or more in order to see higher order effects). While in Firefly the Alliance wasn’t necessarily big because of these reasons, they were very advanced technologically and were the only places that offered opportunities to work on the bleeding edge.

Now before I take this analogy too far, let me speak to the “stealing” side of Firefly. I think that’s really where it begins to fall apart. Hopefully none of the engineers of the future are taking from the large corporations that represent the Alliance (except maybe the contracts they win). Stealing isn’t right and in the show is usually because of necessity; I would never encourage any engineer to be anything but outstandingly ethical. However, there are situations in the show where the crew of the Firefly work indirectly for the Alliance in hard times, which I think is reasonable. In engineering terms, I imagine a small design firm of the future working on fixtures for a large factory that needs to outsource some work. Or working in conjunction on a project because the small team is a preferred vendor for a particular part of a product (the embedded system in a robot, for example) and the large corporation provides “the rest” (the remainder of the robot and the expensive moving parts, to continue the robot example). These are all plausible situations in the future and even happening today.

To compare engineers and engineering firms of the future to the Firefly crew paints kind of a bleak future (if the analogy is to be believed). It will be hard to find work because much of it will be dominated by larger companies. And why wouldn’t it? The corporations offer more manpower, lower costs and the potential to create larger things. However, all is not lost. Smaller engineering groups can offer many things which also have parallels in the Firefly universe. These are lessons which can be used today and are a reason I liked the analogy so much. Let’s go over how and why a smaller engineering crew might succeed.

- The ability to take jobs that larger companies cannot or will not.

- Large companies may not want to take on jobs that are small and do not provide a likely return on investment (ROI). However, a smaller company may be willing to gamble on these sorts of things. Historically, the smaller ideas have larger risks but much larger rewards, which could be beneficial for a smaller company willing to take on some risk. An example might be a new product idea brought to a smaller engineering company that is radically different or not fully funded. By going into a joint venture and partially funding the project (assuming they believe in it), they could see large payoff. The lesson here is to investigate opportunities, but be willing to take risks that larger companies will not.

- In the show, this often meant working with unsavory or misunderstood people in society.

- Agility in all aspects. Smaller companies are more likely to be able to adapt to situations.

- This could mean picking up a new piece of software quicker, responding to a customer’s changing needs quicker, not being bogged down with corporate bureaucracy, being able to fly under the radar of larger competitors, really anything that means you have the advantage as the little guy. The lesson here is to maintain that agility (even if you begin to grow as an organization) in order to succeed.

- In the show, they had lots of tricks up their sleeves to maneuver around the Alliance, often outrunning them or tricking them when in a tough spot.

- Your jobs will be almost entirely referrals.

- Almost all work is found through connections, either by word of mouth recommendations or prior experience with a customer. It’s important to remember that your reputation as an engineer can lead to future success, so to maintain that like you would any other skill. New work will also be an active social task, either asking current connections who needs help or asking for recommendations. And yes, social media can count as a social activity to find new work, though I would not count on it as the only method of finding work today.

- In the show, the reputation of the crew got them jobs and respect while continually mobile and moving from planet to planet. They also had to take a few not-so-fun jobs.

- Trust the people on your team. And make sure you like them.

- If you’re working in a small team, the likelihood that you spend more time with them than your family is pretty high. It’s a reality that smaller businesses don’t have structured hours. That’s because much like the Firefly crew, finding work and getting the job done is all you can do to survive. It’s not until you are successful that you can be choosy about which jobs to take and which you don’t. And in the mean time, the job at hand will be very time consuming; so choose your team wisely.

- In the show the crew was basically like a family and their isolation from others while in space was pretty drastic.

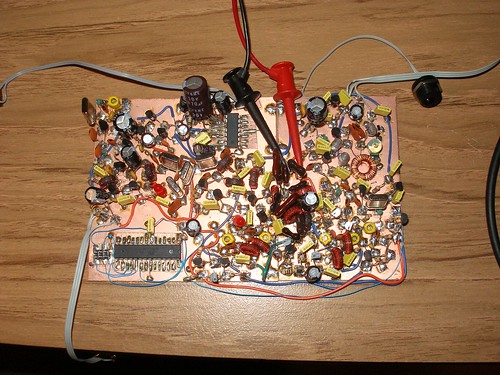

- The focus is on completing the job, not necessarily perfection on all fronts.

- This is exemplified by the scrappy nature of Malcolm Reynolds and his crew and is a necessity for small engineering businesses. When resources and money are tight, the main design constraint is getting the job done. This often means going with proven solutions–so you might start with a reference design or development board instead of trying to start from scratch. This means favoring simplicity and elegance in design solutions over complexity, regardless of how “cool” the complex solution might be. The emphasis on completion can help you plot the fastest course to get to the end of the design, and then focus your energy on removing the obstacles that are guaranteed to pop up (boards are late, can’t get parts, etc).

- In the show they did what they had to and often improvised in order to get the job done. Also since it was a show luck seemed to favor them a few times…

So there you have it: how I view the future of engineering, especially for those not choosing to work for corporations. Both have their benefits and drawbacks, but I believe the choice between the two will continue to be much more polarized. Those choosing the later and striking out on their own may have hardships along the way, but will be rewarded with the freedom to do what they choose and when they want to do it (with the ultimate restriction being putting food on the table).

I’m sure I could compare engineering to a lot of things, but this one seemed to fit. Did I miss any aspects of being a small engineering business? What do you think?