Dr. Dave from Goz7.com was nice enough to drop me a note recently. He is also in the field of analog electronics, but much more experienced and has written some really solid technical articles (such as this recent one about low noise discrete amplifiers).

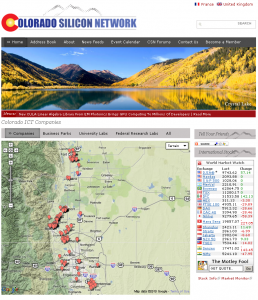

He also mentioned that a friend of his (Bruce Gammill, no relation) was the chairman of a group dedicated to promoting Colorado’s tech region. While I’m not here to say whether the area is the next silicon valley or anything, I do appreciate the fact that it is another resource available for electrical engineers. Specifically, the “beta” section of the site shows a wonderful map of all the companies that are located on the 40 mile corridor from Denver to Fort Collins.

The reason I even mention this at all is that my previous post about where the technical areas are in the US completely glossed over the state of Colorado. While I blame my primitive search capabilities and the fact that the informal survey was based only one who is hiring now, I think it’s still important to point out where there are potential jobs for electrical engineers (and others!). Thankfully readers both here and on the ECE thread of reddit where I sometimes plug my posts were sure to point this fact out to me.

Does anyone know of other “chamber of commerce” type organizations that promote other technical areas in the US or even abroad? Having information about relevant companies in the same location can be a powerful tool for any job search. Using targeted company searches and good job hunting/interviewing techniques, the time searching for a job can be cut down considerably. Looking forward to seeing everyone’s tips!