I’m paying way too much to get PCBs made.

How do I know this? I’ve done it before. I know how many boards I’m making (quite a few!). I know the costs. I know the tradeoffs. And not only that, I’ve gotten quotes from China. I’ve seen how little I can pay (15-20% of what I will end up paying per board).

But that’s not the whole story of course (one sentence statements of my idiocy are left for my Twitter account, this is much more long form). No, this is actually a combination of factors, mistakes and conscious decisions that brings me to this point.

So first, the reveal: I will be using OSHpark to manufacture boards for Contextual Electronics. Here’s why:

- I know James (Laen) and trust him — I have met and had beers with Laen. I’ve bought boards from OSHpark before and had (small) issues quickly resolved. I worked with him for the boards I sent to the Open Hardware Summit. I can gChat with him from time to time. These things go a long way in business, in my book.

- I believe in OSHpark — You probably have been seeing more and more purple boards pop up due to the awesome $5/sq in service for a 2 layer board with soldermask and silkscreen. I can’t imagine how that would have changed my learning process when I started making PCBs and I get to hear how positively this has impacted people in the process of learning. Added bonus: Made in the US of A, baby!

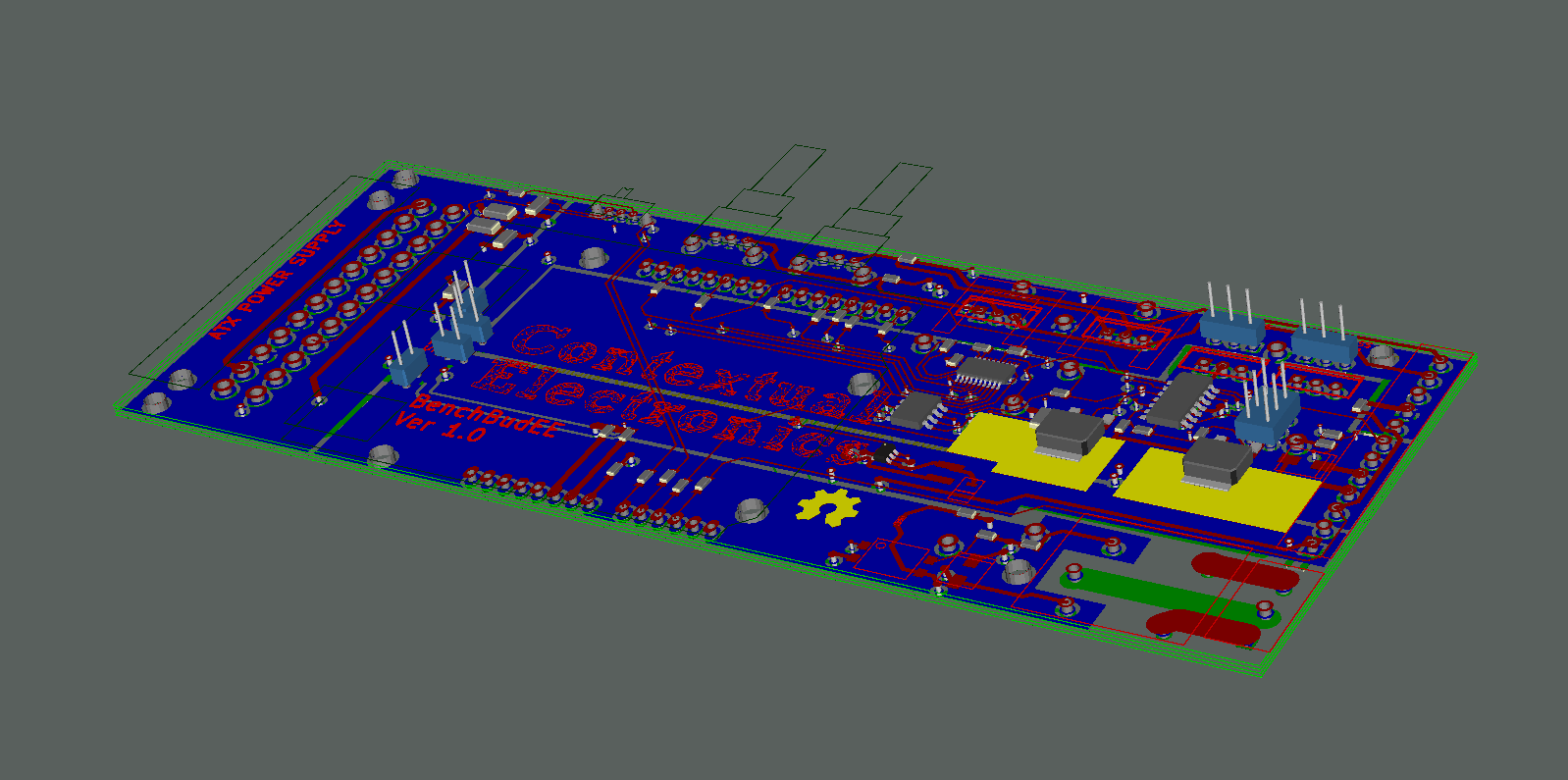

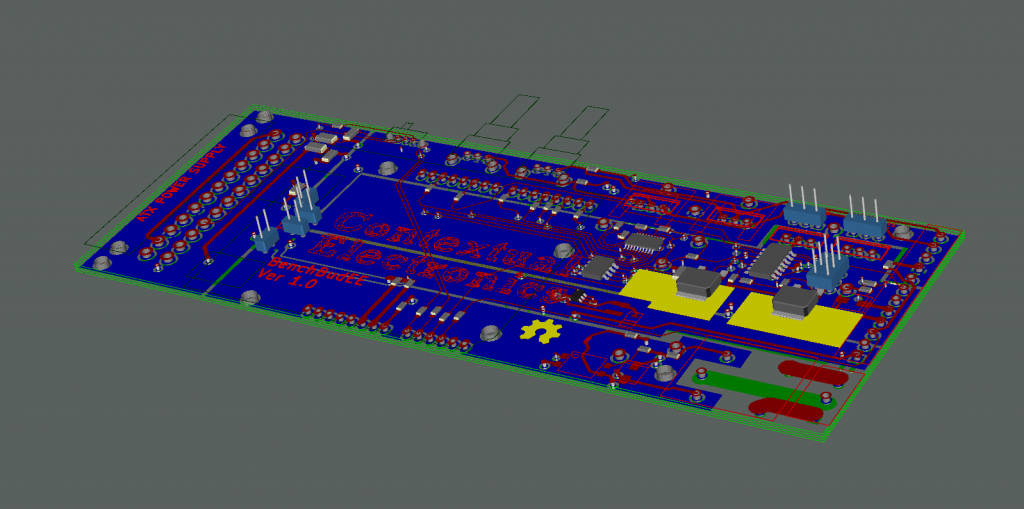

- I got a bulk rate — I was a bit fast and loose with the amount of material I designed into the BenchBudEE. I wanted to have a lot of large mechanical features, I wanted to teach using a 4 layer board and I wanted to be able to plug other boards into the Arduino headers (like a display on top) while still being able to access the auxiliary circuits. All of this added up to 15 sq in of PCB material. Using the $10/sq inch service from OSHpark, that would have been $150 for 3 boards. I am paying less due to the number of CE members getting boards. If you contact them, you might be able to negotiate a discount for bulk orders as well.

- It includes logistics — That is a shipped price. Now, before you tell me how easy it is to put PCBs into an envelope and slap a stamp on them, allow me to tell you: I don’t care. I’m not in the logistical business. Many many people are better at this than I am and I don’t want to get into it. In fact, I’m paying a premium in order to avoid it. Aside from getting set up and thinking about shipping and international issues (customs, transit times, etc), I’m also handing of some of the PCB manufacturing worries (working directly with the fab). As the title implies, I’m in the knowledge business now. I will ship and build hardware for myself, of course…but then I’ll teach others how to do the same for themselves. It’s also much more likely that CE members will be doing low quantity manufacturing and need to learn more about that at first than the high volume stuff that would end up consuming my time.

- It saves me head space — I’m a chronic worrier. I know myself and I know I will stress over perfecting the logistics. Instead, I should spend that time developing more class content for members, including the upcoming Session 1B of Contextual Electronics. Plus, working with people who are good at what they do (like Laen) helps me sleep better at night.

Will I definitely use an outside company to ship boards forever? No, it’s possible that I change my mind in the future and decide to pull this kind of service in house. I have seen my podcast co-host do the same with his shipping, as he works on fulfilling his Kickstarter campaign. This has been an interesting lesson and I’ve talked with Dave quite a bit about his struggles and how it’s paying off. He’s building a foundation for many future hardware campaigns (probably crowdfunded).

Note the differences though: Kickstarter campaigns ship everything at once, in batches (in a best-case scenario). I plan to continue developing and teaching new courses on a regular basis (in batches). However, if I want to allow people to sign up for past courses asynchronously (whenever they want), I may want to continue to offload shipping single units to individuals. Having a service like OSHpark or another fulfillment house do this on a per-person basis (even if at higher cost), could make lots of sense for me so I don’t have to keep inventory. Technically this could already happen as the OSHpark service would allow a student to order boards and all work we do for Contextual Electronics will be licensed as Open Source Hardware. However, negotiating longer term contracts and having distributors (or fulfillment houses) keep them on-hand will completely remove this from my list of tasks.

From a business perspective, I am still making a very healthy margin, as I am selling a “knowledge product” (yak). However, if there were price increases due to changes in business conditions, this could be passed along to members as a “cost of doing the course”. Obviously I will work to reduce that burden on them and the trend points to the cost of PCBs continuing to fall.

It kind of sounds weird, doesn’t it? A hardware guy complaining about making and shipping hardware? But in a world of tight timelines, constrained resources (see also: my time) and my desire to continue developing new stuff, this seems to make sense for me. I would love to hear your thoughts in the comments.