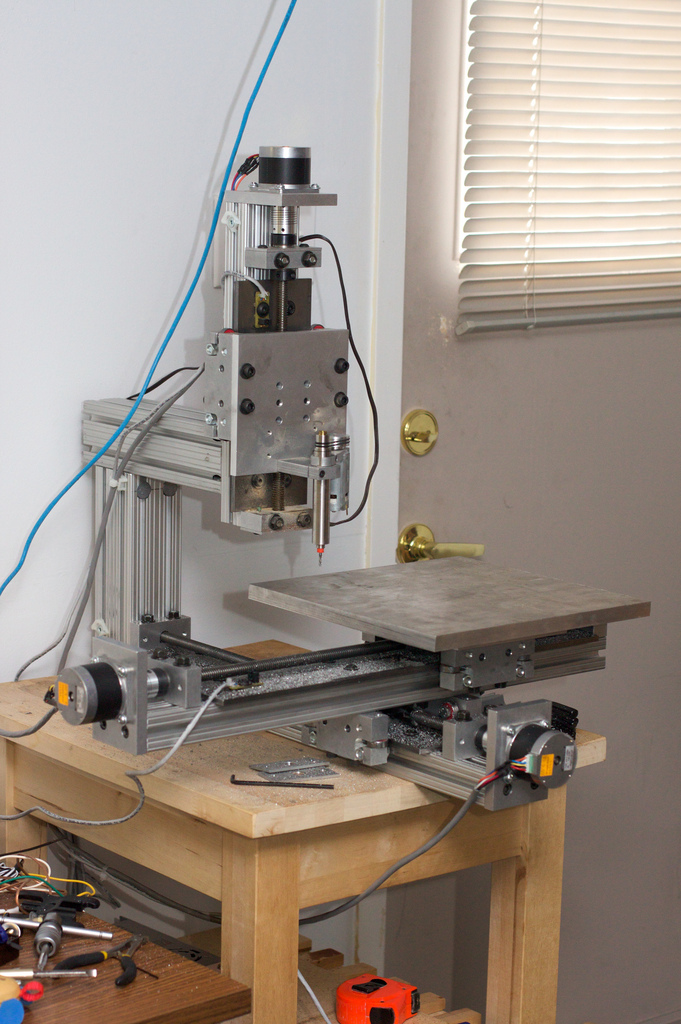

I got the mill out of the box and bolted together. No calibration or leveling yet, but that will come in subsequent videos. Enjoy!

Chris Gammell is an engineer who talks more than most other engineers. He also writes, makes videos and a couple podcasts. While analog electronics happen to be his primary interests, he also dablles in FPGAs and system level design.

I got the mill out of the box and bolted together. No calibration or leveling yet, but that will come in subsequent videos. Enjoy!

This video is showing all of the gear I purchased in preparation for getting my CNC mill up and running. This video shows just about everything except the mill, which will arrive tomorrow. Check out the links below to see all of the stuff I bought, in the event you’d like to purchase some or all of the same gear.

Many thanks to everyone who helped me along so far! I really appreciate it, even though I can’t take everyone’s advice all at once. I hope things continue to get more exciting!

Other podcasts:

Hardware I use:

Software I use:

I often find myself worried about where my job might be in the future.

It’s not that I worry that my current job will evaporate overnight (though that is a possibility for any and all of us). But it’s more of a general concern, because globalization continues its march onward. In general, I find that globalization continues to be a thrilling enterprise because I see what changes it is made in my own life and my own career; electronics really have gotten more exciting since expanding to the worldwide marketplace. The trend is most often notice is the one of general consolidation of duties of an engineer. What this means from an analog electronics perspective, is that my job as an engineer is shrinking. Many of my favorite companies (analog electronics companies) continue to make highly integrated components that I love talking about. In fact, this is why I started ChipReport.TV. I saw it is a general trend that engineers are expected to know more and more about parts without; no allowance is given for being told about them…they just need to know. So I sought to be the one to tell engineers about the parts.

However, I ran into an interesting dilemma and got completely sidetracked from the project, as some of you probably noticed. But this article isn’t about parts, it’s about CNC machines; so let’s talk about the physical world. Specifically, let’s talk about 3-D printing. I have been interested in 3-D printing ever since I first heard about it. I’ve had the interesting opportunity to meet some people involved in the scene, including interviewing one of the former founders of MakerBot and others involved with that project and the Rep Rap project; I even know someone with a great 3D printing company in Cleveland. How cool is that? I wanted to buy my own machine for a long time, but never had the true justification in order to buy one. And so I have trudged along, watching newer and newer 3-D printers being announced. I’ve come close to clicking “Buy Now” on more than one occasion, but thankfully have never pulled the trigger. It’s not from lack of application nor lack of want, but simply the lack of justification for having a device that only prints plastic. In fact, let’s look at some of the applications I’ve seen in my own experience so far:

Are all these practical and necessary in my real life? Who’s to say. Well, my partner, but she’s honestly been winning this battle so far. She makes too much sense for her own good sometimes; I just can’t seem to justify it still.

In all of this, the biggest desire is to change my physical environment. To be able to dream of a component in my mind, render it in a CAD program, introduce it in some low skill, quick turn way. I truly want a fabricator, without any of the overhead, nor training required.

So where did I go from here? How did I go from 3-D printers, to CNC machines, as the title of this article suggests?

I could route PCBs from copper clad FR-4The thing that really kicked it all off was an article I found on a subreddit, /r/hwstartups (one of my favorites). The article described gear making from a hobby CNC machine in order to make a planetary gear setupfor a robot. Granted, I didn’t know what that meant before I started delving into the article, but I soon found that those little gears help increase the torque from a stepper motor in a compact way. Still, it was not the fact that this person was showing me how to make tiny gears, but instead showing me the value of a CNC machine. In fact, it was immediately recognizable how much value it had outside of the 3-D printer (the section comparing the two really helped!). And most importantly, it showed the value and justification I might have in order to purchase one. What were some of these additional characteristics? What else could I possibly make with CNC machine that I could not make with the 3-D printer?

Of course, there are a variety of limitations–not the least of which being my complete lack of knowledge about machining and all things metal work. I never took any shop class in college or high school because I was more interested electronics at the time. Other limitations include cost, time, danger/safety concerns, space for the machine and so on. In fact, I was encouraged by a variety of people to instead utilize the increasing number of options out there for fabrication from services, as opposed to machining or constructing on my own. Services such as Shapeways, Ponoko and others now will provide 3-D prints and laser cut components from acrylic or MDF for a reasonable price, in a short time span. My favorite PCB service, OSH Park, can turn around really high quality, low cost boards in a couple weeks. They’re all really quite a good deals. However, I still find I want the ability to crank out a model at 3 AM in my own basement; I know the likelihood is low that I would need to, but that can make the difference between trying something and not trying something on a project. Plus, I feel like there’s a lot of value in learning this skill and carrying it forward with me through the rest of my career.

Of course, there are a variety of limitations–not the least of which being my complete lack of knowledge about machining and all things metal work. I never took any shop class in college or high school because I was more interested electronics at the time. Other limitations include cost, time, danger/safety concerns, space for the machine and so on. In fact, I was encouraged by a variety of people to instead utilize the increasing number of options out there for fabrication from services, as opposed to machining or constructing on my own. Services such as Shapeways, Ponoko and others now will provide 3-D prints and laser cut components from acrylic or MDF for a reasonable price, in a short time span. My favorite PCB service, OSH Park, can turn around really high quality, low cost boards in a couple weeks. They’re all really quite a good deals. However, I still find I want the ability to crank out a model at 3 AM in my own basement; I know the likelihood is low that I would need to, but that can make the difference between trying something and not trying something on a project. Plus, I feel like there’s a lot of value in learning this skill and carrying it forward with me through the rest of my career.

Lately, I have been finding the benefits of having a platform from which I speak my mind and request help. Specifically, when I put out the call on The Amp Hour for help regarding CNC machines, I had many kind offers of assistance. It must’ve been woefully obvious to my listening audience how little knowledge I actually had in this field. Luckily, I’m not the first electronics nerd to dive into the mechanical world. I was referred to a variety of resources, which I’ll list below:

While I’m still in the process of researching and narrowing the field of potential CNC milling machines (and in reality I’m still determining whether I am going to purchase one at all), I thought I could lay out some of my potential options in order to help meet gather and refine my thoughts on the matter. While I am leaning one way already, I’ll try to remain as objective as possible in case others find this document in the future and are looking for a range of options.

The things listed above actually aren’t CNC machines right out of the gate. more specifically, they’re milling machines; the CNC part you often have to bolt onto them yourself. And for this task, like all things on the Internet, there are people who will gladly sell you something to help you get the job done.

One thing I’ve left out of this entire equation is the issue of software. In machining is not just a CAD program that is required. Once the model has been rendered in a CAD program, you need some way to translate the machine data into lower-level code that CNC machine can then use to carve out a path on the raw material you start with. This is called CAM software. The combination of the two allow you to draw a hole drilled in a block of wood on your computer and then load that into your CNC machine and have it actually drill that hole in a block of wood; pretty neat, eh? I’ll continue to research this as I move into the depths of this hobby but I know there are a variety of open source and paid programs on the market. I’ll most likely choose support and community participation over cost. I’ve learned the hard way that getting stuck with no form of assistance available is a very discouraging path in any new hobby. I may even let cost slide and suppress my inner cheapskate.

Speaking of cost, I feel it’s important to point out here that this is not going to be a cheap hobby. I realize this from the beginning; I was reminded of this with everyone I talk to. It actually brought up an interesting conversation comparing a project (“constructing a CNC machine from scratch”) to a tool (“buy it off the shelf and start using shortly thereafter”); I decided early on that I wanted the latter. While I’m sure that I will learn a lot about CNC machines and stepper motors and everything else involved in computer controlling a milling machine, I’d like to learn that long after I have a couple projects under my belt. Then I can actually make some parts for the second machine from the initial machine. In fact, one of the first projects I dreamed up is cutting the components for a 3-D printer, specifically a Rep Rap. I’m sure this is entirely too ambitious but a dreamer is going to dream. It does show another benefit of a CNC milling maching: I’ll be able to make tools I need in the future. What this all means for me is that I’m going to have to sacrifice some other things in my life. And though it pains me a little bit, I’m actually selling my drum set and saying goodbye to one of my former hobbies. Well, it’s more, “packing up the thing I said goodbye to a long time ago”; I don’t really play drums anymore. Still, it will be nice to see something that brought me so much happiness be transformed into something new that will also hopefully bring me happiness.

So if things all go according to plan (and they never really do, do they?), I will eventually buy a CNC milling machine and start my journey as a hobbyist machinist. I likely won’t think of myself as a hobbyist machinist but instead just someone who wants to make stuff. I hope to document it here and elsewhere around the web and hope that anyone who still happens to read this site might find some useful information from my experiences. And if you happen to have some experience you might want to share with me or share with others in the comments, please do so below.

Many thanks to Nick Carter of Cartertools.com and Philip Friedin of Fliptronics, both of whom offered valuable advice and warnings about getting into this hobby. While I might not take every piece of advice they gave me (nor all of the advice left in the comments), I very much appreciated everyone taking time to explain things to me.

Thanks to UncaughtException and chuckoutrearseats for the pictures.

So I’ve continued to keep myself busy lately. I have a new project called ChipReport.tv. I’ll be reviewing the newest released parts so you don’t have to work so hard to find them.

Here’s the intro video:

And here’s the first installment!

Around here, I hope to do a site refresh soon, since this blog has gotten a little stale. I think I’d like to transition it to more of a traditional “home page” for all the things I’m working on. Comments welcome on any of the above.

No.

You just stop that right friggin now.

Yeah, I’m talkin’ to you, lawyer/investor/clueless people.

Well, if you’re a reader, go read this article from The Economist (my favorite magazine) before we proceed: http://www.economist.com/node/21554540/

The part about Google, Apple, Samsung and other handset manufacturers needing to quickly trade patents seems to make sense at first, right? But that’s not the concern. Those companies have lots of resources at their disposal and I think their rattling of their technology (light?) sabers is just bad policy; they should have figured out that stuff in private, not in courts.

No, the part that bothered me was reading about the exchange itself and how it will exist for future work. I’ve not experienced a visceral reaction like I have to this in a long time. But this is just insane. There is now an exchange that allows you to buy, sell and wait for it…hedge patents.

The comments section of the Economist article belie the idea that an exchange already exists and that it is in a reduced format. However, it is an absolutely ridiculous idea in all its forms. Patents are broken enough as they are. Encouraging trading of these ideas as something that can then be auctioned off to end users (product integraters) does nothing but ramp the price of them through speculation. This does absolutely nothing but impede invention. It further provides firepower for patent trolls like Intellectual Ventures. While I understand the need to actually trade existing patents between companies (even though I don’t always agree with how it happens), it should remain a private affair, if it should happen at all. There needs to be a high barrier to entry for outside people to jump in and try buying and selling things they don’t understand.

I’m not hopeful that this will be regulated or turned down at any point in the future. I can only hope that people continue to open source the things the work on and leave the ridiculous nature of patent trading to the large and hopefully short-lived manufacturers.

Another website? What am I, switching out of electrical engineering and into IT?

Well…no.

This is the site for the podcast mentioned in the last post. We called the first episode, “Jumping Off” and the second episode is about “Feedback”. We hope you like it! Many more themes, discussions and guests are on the way in the coming months.

You can find it over at our new home, The Engineering Commons. Please consider subscribing so you can hear our shows as they are posted. Thanks for listening!

I’m not around here too much anymore. It’s not that I don’t have anything to say, it’s just that I have so many other places to say it. And I may have added another one.

As some you may know, I’m the co-host of an electronics podcast called The Amp Hour. It’s a lot of fun and our listeners run the gamut of hobbyists to professionals. Me and Dave Jones talk about circuits and related topics weekly.

But something has happened lately. I keep trying to draw the conversation away from electronics during the show and into more general engineering topics. I enjoy talking about more general topics such as innovation and the design process. But that’s not what Amp Hour listeners want to hear, they want circuits. We’ve done a couple surveys and each time that comes through loud and clear.

So, I started a second podcast!

I’ve paired up with Jeff Shelton of Engineering Revision. He’s an experienced mechanical engineer who is back in school for his PhD at Purdue and has lots of great experiences to draw on during the show.

This is just the first episode, so we’re looking for two things:

If we keep enjoy doing the show and you enjoy what we have to offer, we’ll find a more permanent home with a website and a feed. Please let us know what you think in the comments!

EDIT: I didn’t realize the widget wouldn’t allow a direct download. If you want the mp3 file all to yourself, you can download the .mp3 here directly.

I’ve looked at a lot of resumes for electronics positions, so I thought I’d share some of my opinions on what should or shouldn’t be on there. Nothing formatting specific, so much as how to get across your interest and passion in electronics. I used examples that are resumes meant for engineering internships, but a lot of the info can be generalized to anyone. Hope you enjoy the video!

Here are those two resumes, if you’re interested: The bad (1st) version and the better (2nd) version.

Oh hey, remember me? Yeah, I’m the guy that’s supposed to be running this site. Sorry for the long absence. I’ve been consulting, recording my electronics radio show, managing a multi-blogger engineer site and even getting married! Jeez, it’s been a busy time. Anyway, things have cooled off a bit, so I’ve freed up some time (for now, never know what’ll happen).

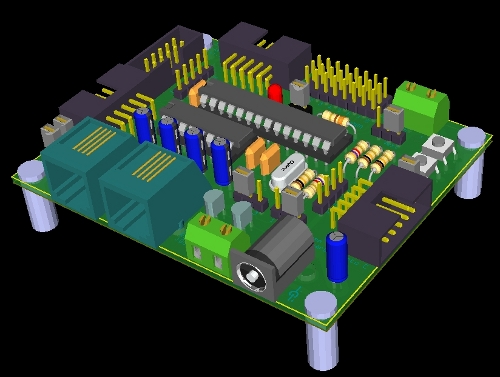

I decided to dive into a new project after a long hiatus from hobby type activity. I plan to put an MP3 player and output stage board into an antique radio enclosure. I also decided to document the process, specifically using the open source board layout program, KiCAD. I’ve been talking about learning the software and doing the videos for a while now, so here it is! The first installment is the schematic capture. I’ll add more as the board gets more complex and I need to dive more into the process of actually getting a board fabbed. I’m excited! Hope you enjoy the video and the ones to come!

[xyz_lbx_default_code]